We Resolve Complex Well Issues

Why Wells Underproduce or Stop Production

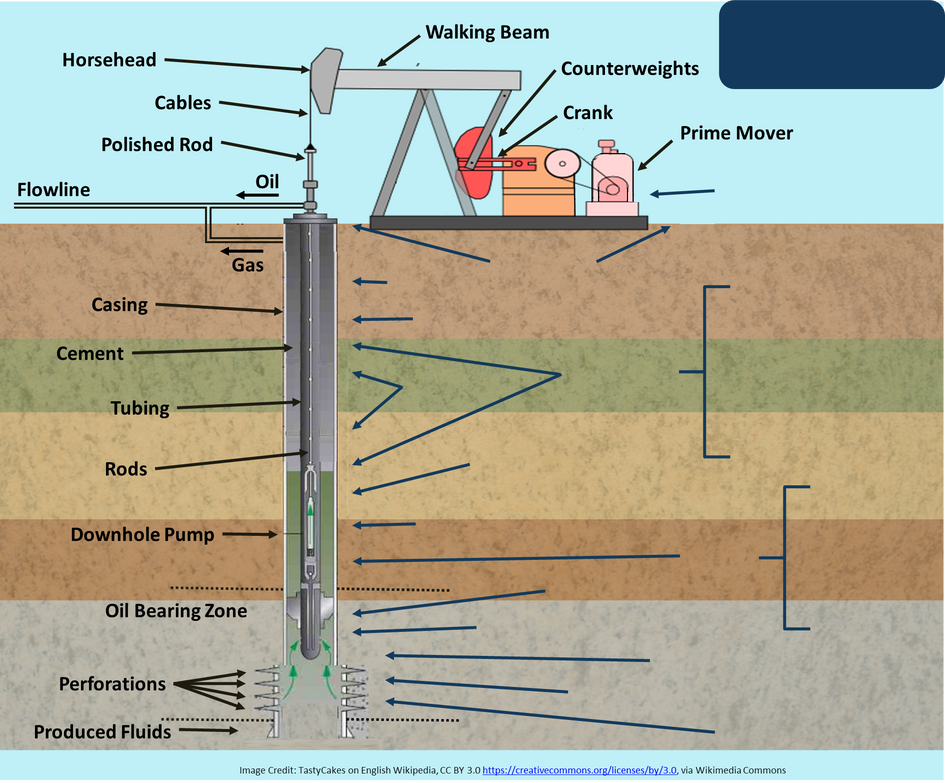

Operational challenges and issues arise in producing wells after the drilling process is complete. Even preventative maintenance can interrupt production.

- Blockages – Obstructions within the wellbore, tubing, and surface equipment constrict fluid movement.

- Sludge – Paraffin, asphaltenes, hydrates, scaling, bacteria, iron sulfide, and other sediment reduce oil flow and cause wellbore instability.

- Scaling – Mineral precipitates reduce flow area.

- Emulsions – Demulsifier separates oil and water to collect oil.

- Corrosion – Minerals, bacteria, and acid cause deterioration.

- Equipment Failures - Mechanical failures and malfunctions result from friction, fluid loss, foam, blockages, and corrosion.

- Water Production – High levels reduce production efficiency. Production chemicals leave toxic water.

- Gas Production – Gas requires flare or utilization.

- Reservoir Management - Reservoirs deplete and pressure declines over time, requiring artificial lift methods to maintain production levels.

- Well Integrity – Design/construction problems and high-pressure/high-temperature extremes compromise well integrity.

- Environmental and Safety Concerns – Inadequate safety and spill protocols fail to protect workers and the environment.

Our Solutions Provide Safe Spill Cleanup

Oil spills have many causes.

- Corrosion, wear and tear, and inadequate maintenance lead to wellhead equipment, pipeline, and storage tank failures.

- Uncontrolled oil blowouts result from pressure imbalances, drilling complications, or safety breaches.

- Accidents during transportation, such as vehicle crashes, pipeline ruptures, or tanker leaks, result in oil spills. Adequate safety measures and environmental safeguards include spill response plans and containment systems.

- Human errors and inaction cause oil spills during drilling, production, and maintenance. Inadequate training increases the odds of mistakes during operations.

- Natural disasters, such as hurricanes, earthquakes, and tsunamis, lead to damaged infrastructure and ruptured pipelines. Deliberate sabotage or vandalism can cause serious damage.

Oil spill damage can be restored.

- The Gunnr series approach to bioremediation uses an eco-friendly with a core fiber blend and indigenous oil-consuming microbes. These biodegradable formulas protect water and land quality while ensuring wildlife safety.

- Gunnr products offer non-toxic, non-hazardous, and non-leaching solutions to remediate oil and hydrocarbon spills in a wide variety of environments, including wells, creeks, ponds, streams, and agricultural fields.

- Gunnr's versatile eco-friendly solutions work in both fresh and salt water environments, tackling crude oil, hydrocarbons, chemicals, and resins from fracturing wells. Gunnr formulations solutions excel at absorbing and cleaning sand, dirt, and materials affected by oil spills, contributing to soil balance.

- Gunnr's durable products can be creatively reused, such as in composting or as sand in playboxes. These products can be burned and used as a fuel source, offering an eco-conscious disposal option.

Our Solutions Prolong Equipment Lifespans

Equipment failure is avoidable.

- Mechanical failures or malfunctions in pumps, artificial lift systems, and production equipment cause unplanned shutdowns.

- Friction wear and tear contributes to mechanical failures and impacts well integrity.

- Corrosion of metallic components leads to equipment failure and production interruptions.

- Foam causes gas locks in the wellbore, preventing upward flow of liquids, interfering with artificial lift systems, and causing wear and tear on pumps and production equipment.

- Fluid loss occurs when undesired loss of drilling fluids or other fluids used in well operations escape into the surrounding rock formations or reservoir.

Tailored, eco-friendly blends protect the well and production equipment at each site.

- The Prima series offers fast, effective biodegradable solutions for removing and inhibiting asphaltene. Prima treatments disperse paraffin buildup and prevent plugging in wellbores, flowlines, and pipelines. Prima formulations reduce viscosity to increase flow and pumping pressure.

- The Gunnr series provides natural bioremediation to resolve oil and hydrocarbon spills on roadways, flooring, and other hard surfaces where spills are hard to contain.

- The Mist series biocides remove microorganisms and prevent microbial attacks. Mist products clean water through extraction. Mist products recover more oil to help cover clean-up expenses with reduced required monitoring.

- The Rōta series reduces friction while protecting against abrasion and deterioration. Rōta products reduce and prevent foaming quickly and effectively under even severe conditions. This eco-friendly series can be added on-the-fly to reduce waste and disposal costs.

- The Hildr series disperses acid corrosion inhibitors for mineral and organic applications. Hildr eco-friendly formulations remove oxides, rust, and other deposits.

Our Solutions Protect Equipment from Foam

Foam interferes with well functions and impacts well productivity.

- Foam is generated in the wellbore, during fluid transfer, and within the processing facilities. Foaming builds as gas disperses in liquid and leads to operational challenges and well issues.

- Foam-related problems raise pumping costs and decrease flow assurance by reducing well productivity, causing gas locking, increased pressure drops, and decreasing lift system efficiency.

- Foam diminishes chemical treatment and intervention effectiveness. Foam increases equipment wear and tear.

- Foam interferes with the separation of oil and water phases, while also deteriorating the stability of the separation. This can lead to operational inefficiencies, equipment damage, and increased management and maintenance costs.

Controlling foam formation is essential to well integrity and efficiency.

- The Rōta series defoamers effectively reduce and prevent foaming in oil pipelines and drilling activities by removing entrapped air and reducing surface tension in drilling muds, crude oil, water systems, and oil systems. Rōta eco-friendly formulations provide resistance to chemical corrosion.

- Rōta defoamer treatments function under severe field conditions in a variety of environments and a wide range of applications. The Rōta series is effective at high temperatures and can be diluted with any hydrocarbon, such as diesel, crude oil, and kerosene.

- Rōta products inhibit foaming quickly and effectively while mixing well with water for cleaning surfaces. Rōta products decrease pump pressure which increases flow.

- The Rōta series can be added on-the-fly to reduce waste and disposal costs.

Our Solutions Protect Equipment from Friction

Friction wear and tear deteriorates vital equipment parts.

- Friction leads to mechanical failures and unplanned shutdowns in critical equipment, affecting overall well integrity.

- Friction limits fluid movement along the wellbore, tubing, and other flow pathways. This resistance slows flow rate, decreasing overall production.

- Friction reduces fluid flow, decreases pressure, generates heat, resulting in increased energy consumption and lower production efficiency. Excessive heat affects equipment integrity and promotes scale formation.

- Friction impacts the entire well, including wellbore tubing, pump and rod string systems, flowlines and pipelines, downhole tools, packer and completion components, wireline operations, casing and cementing processes, and artificial lift systems.

- Friction between casing and cement affects cement bonds strength, leading to well integrity concerns and fluid migration between zones.

Prevent damage and high temperature wear and tear from friction.

- The Rōta series protects drilling equipment operating in diverse environments. Rōta biodegradable treatments dramatically reduce friction by providing protection against equipment abrasion and deterioration.

- Rōta treatments form a torque-reducing film on the drill string and the surface of the mud cake where it applies oil-lubricating properties.

- Rōta lubricants are highly effective in a range of fluids, such as freshwater, a variety of brines, and hydrochloric acid.

- Rōta formulations provide resistance to chemical corrosion and higher temperatures. Rōta products lower pump pressure which increases flow.

- The Rōta series can be added on-the-fly to reduce waste and disposal costs.

Our Solutions Protect Reservoir from Fluid Loss

Fluid loss leaves well components unprotected.

- Fluid loss refers to the unintended loss of drilling fluids or other fluids used in well operations into the surrounding rock formations or reservoir. Fluid loss occurs during drilling, completion, and production.

- Causes of fluid loss include formation permeability, lost circulation zones, high differential pressure, faulty wellbore seals, and chemical reactions.

- Fluid loss increases drilling costs, intensifies wellbore instability, and expands formation damage as well as reducing drilling efficiency.

Prevent damage and high temperature wear and tear from friction.

- The Sigrún series reduces viscosity, enhances flow, and dissolves or disperses organic deposits, such as paraffin and asphaltenes. Sigrún biodegradable formulations facilitate the flowback of frac fluids and reduce breakdown pressures, surface tension, and formation damage.

- Sigrún products improve formation permeability. Prima eco-friendly products reduce viscosity to increase flow and pumping pressure.

- In addition, we add our other product series as applicable to the well-specific causes of circulation and high-pressure issues, faulty seals, and chemical reactions. If wax is identified as an issue, Prima treatments disperse paraffin buildup and prevent plugging, for example.

Our Solutions Break Up Emulsions for Better Recovery

Hard-to-separate emulsions foul surface equipment through pipeline.

- Managing oil and water emulsions is crucial to prevent operational inefficiencies and damage.

- Emulsions form in the wellbore and downhole equipment when oil, water, and gas are produced. Emulsions also occur in surface facilities, pipelines, and water-injection systems.

- Emulsions negatively impact flow, equipment, and separation processes. Emulsions form during fluid transportation through pipelines, especially if the oil-water separation is incomplete.

- Emulsions with high viscosity lead to increased pressure drop, pipeline fouling, and difficulties in separating oil and water at receiving terminals.

- High-viscosity emulsions drop flowline pressure, foul pipelines, and increase demulsifier use.

- Foam hinders oil-water, gas-liquid separations.

- Asphaltenes and bacteria stabilize emulsions.

- Iron influences reservoir emulsion stability. Stable emulsions containing iron particles interfere with oil-water separation in surface facilities.

Breaking up emulsions improves recovery rates and reduces overall waste.

- The Prima series breaks up emulsions, lowers water levels, and enhances recovery rates in diverse conditions. Prima biodegradable products reduce viscosity and lower pumping pressure while minimizing environmental harm.

- Prima products effectively remove oil-wet solids from wellbores and reduce viscosity in high water cut crude. Prima formulations recover more product and reduce waste.

- The Sigrún series reduces viscosity, enhances flow, and dissolves or disperses organic deposits like paraffin and asphaltenes. Sigrún eco-friendly products reduce friction, breakdown pressures, surface tension, and formation damage.

- Prima and Sigrún formulations enhance solubility and prevent water in oil emulsions. Our products provide a biodegradable alternative to HCl for acidizing applications. Prima and Sigrún treatments reduce precipitation while isolating and suspending particulates in a stable base for removal.

- Other Valkyrie Specialty biodegradable products are added to these blends, depending on other conditions present, such as foam, asphaltenes, bacteria, etc.

Our Solutions Control Scaling

Scaling damages equipment and reduces production levels.

- Scaling is the accumulation of solid mineral deposits from produced fluids, leading to blockages in the wellbore, tubing, and equipment.

- Scale deposits reduce flow rates, cause plug perforations, increase pressure, damage equipment, promote corrosion, and raise operating costs.

- Common scaling minerals include calcium carbonate, calcium sulfate, barium sulfate, and strontium sulfate, depending on fluid composition.

- Scaling is managed through chemical inhibitors, mechanical removal, and periodic treatments to prevent or remove deposits.

- Radioactive scales form due to naturally occurring radioactive materials (NORM) in subsurface formations, posing safety and environmental risks. Radium, uranium, and thorium isotopes make scales radioactive, necessitating safety protocols and disposal measures.

Tailored blends break up scaling and protect against the elements causing local deposits.

- Hildr formulas successfully descale wells, perfs, pumps, rods, tubing, flowlines, and pipelines without causing corrosion issues or harm to steel and galvanized surfaces.

- Hildr eco-friendly products use descalers, anti-corrosives, and scale inhibitors to remove and prevent deposits and blockages that slow production and shut down operations. Preventing buildup with a scale inhibitor effectively keeps oil processing systems clean and minimizes equipment downtime.

- The Hildr series uses proprietary dissolving chemistry to achieve the fastest, most efficient, and broadest applications of similar treatment chemistries to date. Hildr treatments are a remarkably effective alternative to the use of hazardous chemicals for scaling removal.

- Hildr formulations use a neutral pH that won't harm metal or galvanized steel. Hildr products target blockages without altering the treated area’s chemical composition.

Our Solutions Treat and Prevent Corrosive Damage

Corrosion causes expensive equipment failures and production interruptions.

- Corrosion is a natural deterioration process occurring when metal surfaces react with the environment. Corrosion degrades equipment, leading to shortened operational lifespan, costly repairs, downtime, and safety risks.

- Fluid composition, temperature, pressure, and corrosive substances influence corrosion.

- Damage from scales, acid, H S, CO , iron, FeS, and bacteria reduces efficiency and poses hazards. Iron in steel alloys rusts when exposed to the well environment.

- Scaling and corrosion from the accumulation of paraffin, asphaltenes, sludge byproducts obstruct wellbore and production equipment.

- Biocorrosion corrodes well components, leading to structural damage and equipment failures.

- Certain bacteria, like sulfate-reducing bacteria (SRB), accelerate corrosion in wellbore materials and cause leaks and complications.

2

2

Corrosion can be treated and prevented

to save equipment and keep wells running.

- The Hildr series disperses acid corrosion inhibitors for mineral and organic applications. Hildr formulations remove oxides, rust, and other deposits.

- Hildr biodegradable products treat and prevent corrosive damage from scales, asphaltenes, acid, H S, CO , iron, FeS, and ferrous metals like steel. Hildr products eliminate microbial-induced corrosion.

- Hildr formulations stabilize clay either temporarily or permanently, depending on the specific fine type and degree of swelling. Hildr products function at high pH and high temperatures.

- Continuous injection of Hildr formulations removes buildup, maintains salt solubility, provides long-term corrosion, and prevents bacteria growth.

- The Sigrún biodegradable series reduces viscosity, enhances flow, and dissolves or disperses organic deposits like paraffin and asphaltenes. Sigrún products contain anti-corrosives to protect well components from reoccurring corrosion.

2

2

Our Solutions Prevent CO Corrosive Damage

2

Naturally occurring in oil reservoirs, CO aids in enhanced oil recovery.

- Some oil reservoirs contain naturally occurring CO either dissolved in the oil or as free gas.

- CO is injected into wells for enhanced oil recovery, sourced from industrial processes or natural CO reservoirs.

- Microorganisms in certain reservoirs produce CO as they metabolize organic matter in rock.

- CO forms through inorganic reactions, like the thermal decomposition of carbonate rocks. CO migrates from neighboring geological formations over extended periods.

- CO enters the wellbore during drilling or operations, particularly when drilling through formations rich in CO .

2

2

2

2

2

2

2

2

2

CO treatments improve flow and recovery rates, while preventing corrosion.

- The Prima series reduces viscosity, increases flow, and lowers pumping pressure. Prima treatments break up emulsions, lower water levels, and enhance recovery rates in diverse conditions.

- The Hildr series has descalers, anti-corrosives, and scale inhibitors to remove and prevent reoccurrence of buildup and blockages that not only slow production but also shut down the operation.

- The Hildr biodegradable series removes scale and prevents buildup. Hildr products treat and prevent corrosive damage. Hildr treatments stabilize clay either temporarily or permanently, depending on fine type and degree of swelling. Hildr treatments disperse acid corrosion inhibitors for mineral and organic applications.

2

Our Solutions Prevent H S Reservoir Souring

2

H S souring affects production, corrodes equipment, and reduces product value.

- H S is highly toxic, corrosive, and poses safety risks to well site personnel. Souring affects production rates, well integrity, equipment condition, reservoir permeability, worker safety, and environmental safety.

- Souring is caused by a bacteria-metabolizing sulfate that produces H S, which contaminates oil and corrodes wellbore equipment, pipelines, and surface facilities.

- H S souring affects produced fluid quality and accelerates microbially influenced corrosion (MIC) in wellbore and production facilities.

- Sour crude oil or gas can be less valuable and more challenging to process, affecting reservoir pressure maintenance strategies.

2

2

2

Versatile solutions for H S souring and frac water disinfection also control SRB.

- The Vápn series reduces H S and sulfur corrosion, neutralizes hydrogen sulfide, and controls sulfate reducing bacteria (SRB). Vápn eco-friendly treatments disinfect frac water, which prevents groundwater contamination.

- Vápn products use a PH-neutral H S scavenger to capture sulfur and prevent corrosion damage. Vápn treatments lower operating costs and improve system reliability, disinfect frac water, and prevent groundwater contamination.

- Vápn products purify and deodorize oil and gas. Vápn products treat and resolve corrosion and sour well problems in high sulfur fields.

- Vápn treatments are frac fluid compatible and pH neutral, breaking down frac fluid into salt and water. Vápn treatments can be used in place of bleach and glutaraldehyde.

2

2

2

Our Solutions Prevent FeS Corrosive Damage

Iron sulfide (FeS) scales hinder production and pose safety risks.

- Iron combines other minerals, such as iron sulfide (FeS) or iron carbonate (FeCO ), to form scales that accumulate on wellbore surfaces, equipment, and downhole tools.

- FeS has a significant impact on well operations, affecting production rates, well integrity, equipment condition, and reservoir permeability.

- The corrosion caused by FeS reaction with water and oxygen weakens well metal components. Corrosion leads to equipment failures, leaks, and sludge formation.

- FeS combines with sand, paraffin, and asphaltenes to form sludge that restricts hydrocarbon and fluid flow in the wellbore, equipment, and pipelines. Flow restriction leads to operational challenges and reduced production rates.

- FeS reacts with acids to generate toxic and corrosive hydrogen sulfide (H S) gas. H S poses safety risks for workers and contributes to corrosion and equipment damage.

3

2

2

Iron sulfide (FeS) treatments ensure efficient operations and prevent shutdowns.

- The Prima series reduces viscosity, increases flow, and lowers pumping pressure. Prima products break up emulsions, lower water levels, and enhance recovery rates in diverse conditions. Prima biodegradable formulations reduce viscosity and lower pumping pressure.

- The Hildr series has descalers, anti-corrosives, and scale inhibitors to remove and prevent reoccurrence of buildup and blockages that slow or even shut down operations.

- Hildr eco-friendly treatments remove and prevent scale buildup. Hildr formulations treat and prevent corrosive damage. Hildr treatments stabilize clay either temporarily or permanently, depending on fine type and degree of swelling. Hildr treatments disperse acid corrosion inhibitors for mineral and organic applications.

Our Solutions Control Sludge

The composition and formation of sludge damages equipment and increases costs.

- Sludge impacts production, well integrity, equipment condition, and reservoir permeability. Factors like temperature and pressure changes trigger precipitation as fluids move from the reservoir to the surface.

- Sludge may contain paraffin, asphaltenes, scaling, bacteria, iron sulfide (FeS), sand, and other sediment. Sludge causes fluid flow reduction, blockages, equipment fouling, and equipment failure.

- Reservoir conditions, water intrusion, and nutrient availability create favorable environments for bacterial growth, contributing to sludge formation.

- Sludge contributes to equipment erosion and wellbore instability, requiring additional maintenance.

- Sludge requires costly remediation and maintenance that raises operational expenses and extends downtime. Sludge obstructs oil flow, damages the wellbore and equipment, and poses safety and environmental hazards.

Quickly eliminate paraffin and asphaltene while preventing scale buildup and corrosion.

- The Prima series rapidly eliminates paraffin and asphaltene deposits. Prima biodegradable products reduce viscosity, increase flow, and lower pumping pressure. Prima products break up emulsions, lower water levels, and enhance recovery rates across diverse conditions.

- The Hildr series uses specific descalers, anti-corrosives, and scale inhibitors to remove and prevent scale buildup and corrosive damage. Hildr biodegradable products stabilizes clay either temporarily or permanently, depending on fine type and degree of swelling. Hildr products disperses acid corrosion inhibitors for mineral and organic applications.

- Prima and Hildr products are biodegradable alternatives to hazardous chemicals commonly used.

Our Solutions Clear Paraffin Blockages

As paraffin accumulates on surfaces, it restricts flow and reduces productivity.

- Paraffin is a hydrocarbon compound that precipitates from crude oil as it cools, particularly when oil is transported from high-temperature environments to cooler conditions.

- Paraffin accumulates on the surfaces of well tubing, pipelines, and production equipment. Buildup restricts oil flow, impeding efficient fluid movement through the production system.

- Paraffin cause blockages in pumps and valves, affecting their performance and potentially leading to equipment failures.

- Paraffin buildup in the wellbore restricts oil flow from the reservoir to the wellbore, reducing well productivity.

- Paraffin impacts flow assurance, which is the management of hydrocarbon flow from the reservoir to the processing facilities.

- Paraffin issues pose safety risks to workers during well intervention activities.

Paraffin treatments remove deposits to enhance flow and minimize maintenance.

- Prima eco-friendly treatments offer fast, effective solutions to remove paraffin plugging in wellbores, flowlines, and pipelines. The Prima series rapidly eliminates paraffin deposits using a highly efficient paraffin and resin remover.

- Prima treatments disperse residuals to prevent the reoccurrence of buildup and blockages that can not only slow production but also shut down the operation.

- Prima formulations break up emulsions and lower water levels for higher recovery rates.

- The Prima series reduces the need for additional monitoring or maintenance by way of employees.

Our Solutions Clear Asphaltene Blockages

Asphaltene deposits reduce productivity, formation damage, and flow assurance.

- Asphaltenes are complex, high-molecular-weight compounds found that precipitate from crude oil due to changes in temperature, pressure, or composition, leading to deposition on wellbore surfaces, tubing, and production equipment, resulting in flow restrictions and reduced productivity.

- Asphaltenes cause formation damage, reducing reservoir permeability and overall productivity. Asphaltenes contribute to wellbore instability, complicating drilling operations and increasing equipment failure risk.

- Asphaltenes interfere with flow assurance to cause blockages in pipelines, well tubing, and production facilities, leading to operational challenges and increased maintenance.

- Asphaltenes stabilize oil-water emulsions, complicating separation, downstream processing, and refining efficiency.

- Asphaltenes foul components, including pumps, valves, and separators, reducing equipment efficiency, and increasing operating costs.

Asphaltene removal enhances recovery rates and protects equipment from corrosion.

- The Prima series eliminates the nuisance of asphaltene accumulation in diverse environments. Prima biodegradable treatments effectively break down and remove asphaltene blockages that impede production and lead to operational shutdowns.

- Prima products eliminate asphaltene deposits and reduce corrosion levels. The Prima series provides protection against reoccurrence and further build-up to maintain fluid flow and production levels.

- Prima products break up emulsions and lower water levels for enhanced recovery rates under varied conditions.

- Treatment with the Prima series prevents the disruptions asphaltenes commonly cause. Prima treatments reduce the need for additional employee monitoring.

Our Solutions Effectively Manage Bacteria

Well bacteria reduce productivity, damage equipment, and increase sludge.

- Bacteria are a persistent, naturally occurring challenge for well operations, with additional bacteria introduced by equipment contamination.

- Bacterial overgrowth leads to increased water production, which restricts oil flow and reduces well productivity. Reservoir conditions, water intrusion, and nutrient availability promote bacterial growth, and sludge formation.

- Bacteria alter oil composition, accelerate equipment degradation, and damage reservoir permeability. Bacteria stabilize emulsions, hindering separation processes. Bacterial growth results in biofilm formation. Bacterial slimes block screens, perforations, and flow pathways.

- Bacteria metabolize sulfur compounds, leading to deposit formation, such as FeS and sludge buildup.

- Sulfate-Reducing Bacteria (SRB) generate H S gas, which is toxic, corrosive, forms solid compounds like metal sulfides, and contributes to sludge formation. SRB convert CO into H S gas through sulfate reduction.

2

2

2

Bacteria treatment neutralizes microorganisms and prevents scale buildup and corrosion.

- The Prima series eliminates paraffin and asphaltene deposits. Prima biodegradable products break up emulsions and lower water levels for higher recovery rates. Prima products reduce viscosity to increase flow and lower pumping pressure.

- Mist biocides rapidly eliminate microorganisms and prevent microbial attacks, enhancing oil recovery. Mist biodegradable products neutralize salt water, leaving produced water suitable for reuse and removing that hazard around the well.

- Mist products in H O acts as a disinfectant upon contact. The Mist series removes buildup without damage, reduces odors, and disturbs bacteria while preventing growth.

- The Hildr series removes scale and inhibits deposit buildup. Hildr eco-friendly products treat and prevent corrosive damage. Hildr treatments provide either temporary or permanent clay stabilization, depending on the type and swelling characteristics.

- Hildr products disperse acid corrosion inhibitors. Hildr formulations eliminate microbial-induced corrosion, remove buildup, and prevent bacterial growth.

2

Our Solutions Clear Iron-Related Blockages

Iron-related scaling damages equipment and requires increased maintenance.

- Iron-related scaling reduces reservoir permeability, which affects overall well productivity. Iron-related corrosion and scaling affect wellbore and completion equipment.

- Iron combines with other minerals to form scales like iron sulfide and iron carbonate, which causes flow restrictions and blockages.

- Well tubing and casing corrosion undermine well integrity. Iron-related scaling and corrosion reduce efficiency in downhole pumps and artificial lift systems.

- Formation water dissolves iron leads corrosion, scaling, and damage. Iron stabilizes emulsions formed during production, making oil-water separation difficult.

- Iron causes fouling of processing equipment, including water treatment and separation units.

Treatment of iron-related scaling enhances flow and protects against corrosive damage.

- The Hildr series removes deposits and inhibits corrosive damage. Hildr eco-friendly treatments remove scaling, treat damage from corrosion, and stabilize clay temporarily or permanently, depending on fine type and degree of swelling.

- The Hildr series is a diverse line that can dissolve iron sulfide salts with the added benefit of preventing NORM (Naturally Occurring Radioactive Material) rich scales.

- The Hildr series offers descalers, anti-corrosives, and scale inhibitors to prevent reoccurrence of deposits that build up to block impact production.

- Prima biodegradable treatments break up emulsions and lower water levels for higher recovery rates. Prima works in diverse conditions, reducing viscosity to increase flow and lower pumping pressure.

Our Solutions Keep the Water Supply Safe

Production water levels and toxicity disrupt recovery and reduce efficiency.

- High water production levels displace oil in the wellbore, channeling water into the wellbore and displacing oil, particularly in mature reservoirs. Water enters the well with oil, reducing oil recovery efficiency.

- Formation water in reservoirs varies in composition, potentially containing contaminants. High salinity in formation water causes scaling and corrosion in wells and production facilities.

- Produced water may contain heavy metals, posing environmental risks and complicating treatment. Water in and around wells becomes toxic from exposure to hydrocarbons, chemicals, and other natural substances.

- Bacterial growth in wells causes biofouling, corrosion issues, and increased water levels. Overgrowth of bacteria stabilizes emulsions and decreases production.

Protect well water supply, neutralizing salt water and ensuring clean water reuse.

- Continuous injection of Hildr eco-friendly treatments keeps salts soluble, maintains pH and temperature, prevents corrosion, and limits bacterial growth.

- The biocides in the Mist series rapidly remove microorganisms and prevent microbial attacks to improve oil recovery.

- Mist biodegradable treatments disinfect fracking water and prevent groundwater contamination. Mist neutralizes salt water, purifying produced water for repeated reuse and removing the salt water hazard from the well area.

- Gunnr biodegradable treatments use a core fiber blend and indigenous oil-eating microbes to protect water and land quality while keeping wildlife safe. The Gunnr hydrophobic product for contaminated freshwater removes only oil and leaves the water clean.

Our Solutions Control Formation Fines

Formation fines impede reservoir permeability and damage formations.

- Formation fines (fine reservoir rock particles suspended in produced fluids) migrate through the reservoir and wellbore to accumulate in the near-wellbore region.

- Fines block pore spaces within the formation and natural flow channels in the reservoir, diminishing permeability and hindering hydrocarbon flow to the wellbore.

- Fines damage the wellbore and production equipment, such as pumps and tubing. Produced fluids increase viscosity and become more challenging to lift and transport fluids to the surface without losing production efficiency.

- Sand and fines are produced along with oil and gas. Sand erodes downhole equipment, leading to maintenance and operational challenges.

- Formation fines lead to reduced reservoir permeability, wellbore damage, increased fluid viscosity, formation damage, and sand production.

Clearing fines and inhibiting their development protects formations and reservoirs.

- The Hildr series has descalers and scale inhibitors to remove and hinder crystal and scale growth, preventing buildup and blockages. Hildr biodegradable products remove scale deposits, such as calcium, magnesium, and barium carbonates as well as heat scale, oxides, and other deposits.

- Hildr formulations target heavily scaled areas without altering chemical composition, using neutral pH that won't harm metal or galvanized steel. Hildr products eliminate the need for hazardous chemicals, such as fluoride commonly used to remove scaling.

- Hildr environmentally friendly tools prevent NORM (Naturally Occurring Radioactive Material) rich scale development.

- Sigrún biodegradable treatments is broad-spectrum, high-calcium tolerant, and water-soluble scale inhibitors that remove blockages by dissolving and dispersing deposits.

- Sigrún products prevent scale formation in oil field brines, impeding crystal growth responsible for scale development and accumulation. Sigrún products are designed to work in high temperature and high pH environments.

Our Solutions Protect Reservoirs

Reservoir management optimizes oil recovery and prevents reservoir depletion.

- Reservoir management is crucial for optimizing oil recovery and involves strategies to maintain reservoir pressure, manage fluid movement, and enhance recovery techniques.

- Reservoir pressure decline is a common challenge, requiring the use of artificial lift methods like pumps to maintain or increase production.

- Reservoir depletion occurs as hydrocarbons are extracted, influenced by factors such as reservoir size, production rate, and reservoir pressure decline.

- Managing water production is essential as excessive water reduces oil recovery efficiency and accelerates reservoir depletion. Gas cap depletion, reservoir heterogeneity, and economic factors also impact reservoir depletion.

- Reservoir management strategies influence production techniques. Effective reservoir management is crucial for maximizing oil recovery.

Reservoir management offers solutions for cost-effective well maintenance.

- The Hildr series removes scale, treats damage from corrosive elements. and prevents additional deposits and corrosive deterioration.

- Hildr eco-friendly treatments control clay as well as clean, degrease, and remove oxides, heat scale, rust, and other deposits.

- Continuous injection of Hildr products keep salts soluble, which maintains pH and temperatures, providing long-term prevention of corrosion and bacteria growth.

- The Rōta series reduces friction in different fluids. Rōta eco-friendly treatments prevent foaming even under severe conditions. Rōta formulations protect against equipment abrasion, offering cost-effective solutions.

- Rōta formulations are suitable for capillary string treatments, and wellbore cleanings, for example. Rōta treatments significantly reduce viscosities with ultra-heavy hydrocarbons, achieving viscosity rate reductions up to 70%.